Reduce your energy consumption by up to 20% with hydraulic re-balancing

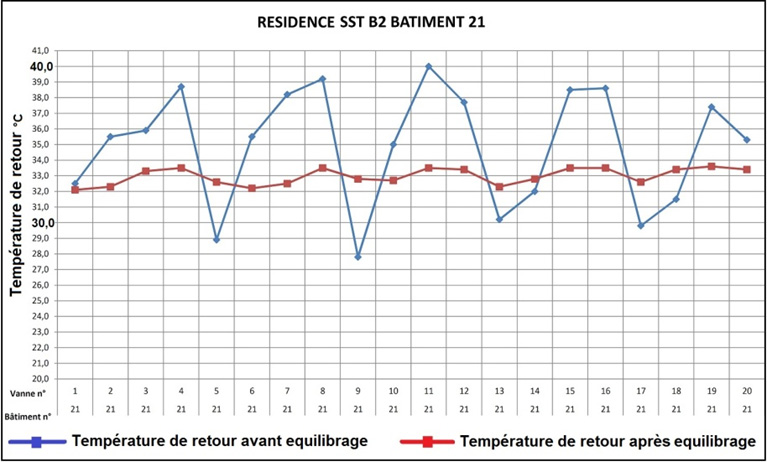

The device standardizes the average temperatures of the units to be balanced.

Hydraulic re-balancing by standardising return temperatures consists of synchronizing the return temperatures of the units to be balanced (when the building concerned has been subject to homogeneous thermal renovation (*)).

(*) Renovation consisting of the replacement of all the windows and/or the insulation of all external vertical walls can be considered as being thermally homogeneous.

The principle is an old one but the possibility of achieving a good result easily and rapidly is recent.

The procedure allows in particular to compensate for significant line losses from old supply systems by controlled excess supply of external units.

Figure 1 : Equalisation of return temperatures of under-floor heating loops

When the building has been subject to thermally heterogeneous renovation, it is possible to regulate different return temperatures for each unit, if the hydraulic supply is coherent with localised insulation operations. For example, it is easy to calculate and to lower the return temperature of outside lines situated under terraces which have been specifically insulated.

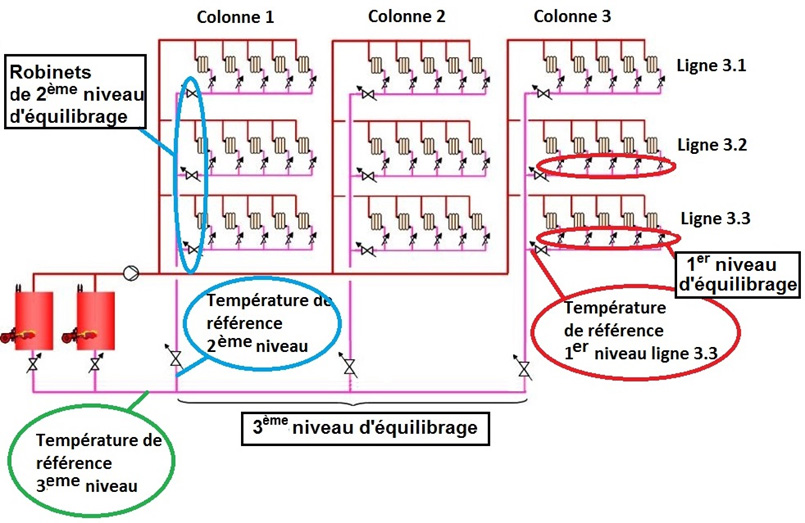

This procedure can be applied to all levels of balancing (figure 2), all types of heat emitters (including under-floor heating) and all types of pipework in good working order.

Figure 2 : Balancing levels and reference temperatures

Advantages of the method

The main advantages of the Equilog method:

- Allows balancing which is perfectly compatible with the type of heating concerned, without unreliable thermal or hydraulic readings

- Allows significant line losses (a fall in water supply temperature) to be taken into account for old water heating supply systems

- Allows direct implementation during the heating season enabling the result to be checked immediately.

- Allows the processing of all types of balancing valves whether of the volumetric type or not (possibility of measuring flow rates).

- Avoids or limits the need to drain the system

- Allows the user to benefit from energy saving allowances and to be eligible for loans from appropriate agencies

- Provides up to 20% in energy savings

Simple method implementation

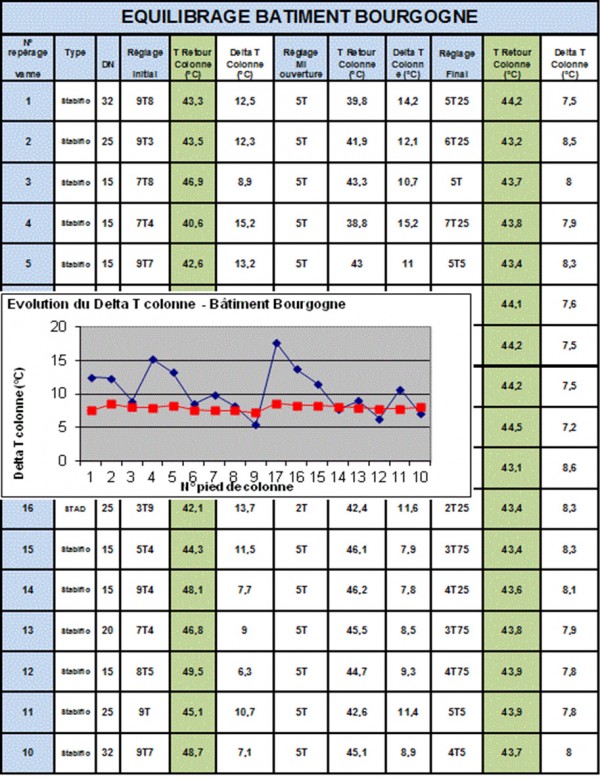

The method consists of setting a fixed initial temperature, and after thermal stabilising, aligning the return temperatures of the units to be processed with the average return temperature, known as the “reference temperature”. (Figure n° 2).

The method consists of setting a fixed initial temperature, and after thermal stabilising, aligning the return temperatures of the units to be processed with the average return temperature, known as the “reference temperature”. (Figure n° 2).

Beginning with the highest balancing level, the valve groups of the same level are dealt with, allowing the processing of large networks by sequence, carried out in only a few hours.

The operation is undertaken for outside temperatures lower than 12°C (or higher, including off heating season periods, if the premises are unoccupied).

Outside the heating season the systems are listed and labelled, flushed out and pipework replaced or installed.

Because of the difficulties of access to the piping, the balancing concerns, as a general rule, the 2nd level and those higher. In the case of supply systems to under-floor heating and tertiary buildings, the 1st level can also be processed.

Following these operations a detailed report is provided including the initial and final situation of the network in terms of return temperature and valve settings.

Figure 3 : Following these operations a detailed report is provided showing the initial and final situation of the network.